| Company Profile |

| LANDMARKS OF HISTORY : |

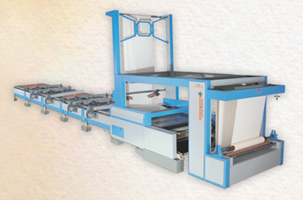

SCREENOTEX ENGINEERS PVT LTD was established and incorporated in the year 1993 by vibrant and resourceful entrepreneurs for the manufacture of Flat Bed Screen Printing Machines.

- The Company’s flagship-venture was ‘Precise & Perfect Engineering Company’ setup in the year 1989 and in entirety almost for two decades the Company is in the service of Indian Textile Industry by supplying Flat Bed Screen Printing Machine, Accessories and Spares giving emphasis on precision of engineering, absorption of new technology and world-class quality standards.

- By now we could supply more than Twelve Hundred Flat Bed Screen Printing Machines apart from few Machines exported to Indonesia along with Bangladesh and African Countries.

- Complete Machinery for a Textile Processing Unit setup on Turnkey basis in Malavi (Africa) was supplied through an Indian counterpart of the Project.

- Cater the needs for Textile Processing Machines from the manufacturing-kitty of Associates

|

|

|

| FOCAL POINTS IN ACTIVITIES : |

- The R & D activities taken on hand is concerted on building innovative aspects in the Machines manufactured by the company looking to the future needs of Fabric Printing Industry.

- At every stage, emphasis is ensured on precision of engineering, design modification, continuous development, absorption of sophisticated technology and quality standards

- The Company tries to provide greater importance on customer value at every stage, Introduce new models of Machines with user friendly and innovative features.

- Mission of the Company is to supply dependable and quality Machines backed by proper after sales services.

|

|

| CORPORATE VALUES : |

- To provide greater customer value always at every stage by knowing market needs

- To strive for achieving growth and leading position in the Market

- To improve continually the effectiveness of quality management system duly creating an environment of teamwork and innovative approach

- Adoption of fine tuned quality methods and standards

- Supply of dependable quality Machines backed by expertise and innovative technology

|

|

|

| |

| CAPABILITIES AND POTENTIALITIES : |

- Well-equipped in-house manufacturing, fabrication and assembly set-up

- Machine shop to carryout precision and heavy jobs

- Integration and interfacing of relevant equipments for optimum performance

- Stage wise inspection facilities in house and at Vendors workshop

- Machine start-up assistance and commissioning

- Prompt and qualitative Maintenance services

|

|

|

|

| QUALITY CONTROL AND ‘R & D’ ACTIVITIES : |

- A team of qualified and experienced engineers, technicians, work harmoniously in tandem towards building brighter innovative aspects from theoretical techniques looking to the present and future needs of Fabric Printing and Processing Industry using the innate wealth of creativity and knowledge.

- The Machines and equipments of our workshop is maintained, repaired and calibrated periodically by the maintenance staff of the company and if need be by availing expert services from outside.

- A permanent chain of suppliers and vendors developed by the company supply raw materials, spares and components as per standard specifications and drawings. Each and every raw materials, spares and components are thoroughly inspected by the Inspection Department against quality; quantity, material, specifications, dimensions, and records and those conforming to the parameters are only taken into production/assembly.

- Fabricated structures, machined, welded, coated, painted and polished components and parts are inspected again before taking those items for assembly of the Machines.

|

|

|

| |

|

|