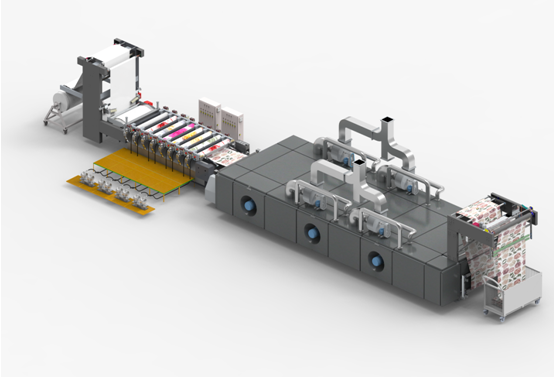

| Rotary Screen Printing Machine |

BENEFITS |

SALIENT FEATURES |

- COST SAVING

- TIME SAVING

- LABOUR SAVING

- SPACE SAVING

- WATER SAVING

- COLOUR SAVING

- FAST PAYBACK

- ENVIRONMENT FRIENDLY

|

- Each screen is independently driven

- Printing paste is fed by special pumps individually to the different screens

- print paste level in the rotary screen is automatically and constantly controlled

|

|

|

|

|

| |

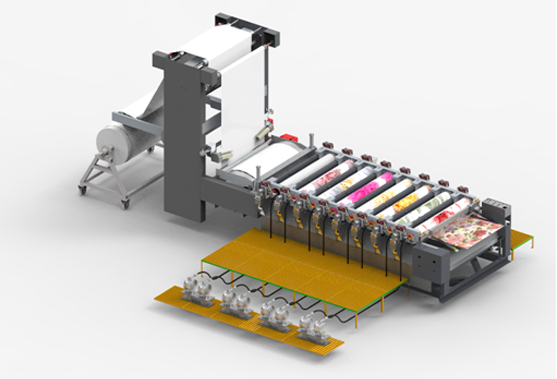

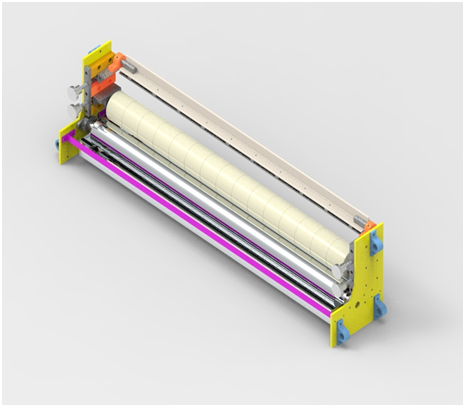

| PRINTING ZONE |

|

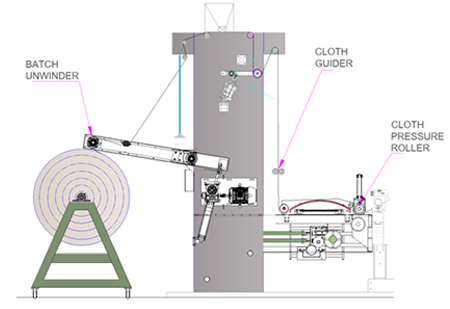

Infeed options

|

|

| |

Features |

- Batch unwinding

- High entry for crease less fabric feeding

- Cloth tensioning device

- Electromagnetic cloth guider

- Band plate with electric heater

- Dust collector (optional)

- Knitted, lycra& other delicate fabrics uses standard spreader unit (optional)

|

|

|

| |

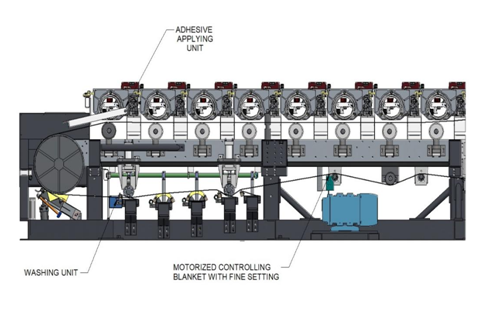

| PVA-GLUING UNIT (OPTIONAL) |

- PVA glue application unit through rubber roller and segment device.

OR

- Adhesive applying application unit and adhesive stripping unit for fine layer adjustment rubber squeegee.

|

Gluing unit with stainless steel tray and segment type brush to adjust fabric width |

|

| |

| Rotary SCREEN PRINTING MACHINE TECHNICAL DATA |

| 1 |

Standard Printing width |

1280, 1620, 1850, & 2250 |

| 2 |

Printing repeat |

64, 82, 91.4, 101.8 cms. |

| 3 |

Printing speed |

8 to 80 mts./min. |

| 4 |

Nos. Of colours |

8,10,12,16,20,24 |

| 5 |

Suitability of cloth |

Cotton, Viscose, Polyester, Knitted, Lycra, etc. |

| 6 |

Drive of the M/C |

A.C. variable-inverter drive & All servo drive |

| 7 |

Dryer type |

Oil / Gas / Steam heated |

|

Drive Option : |

- A.C. Variable-inverter drive

- All servo individual head servo motor with drive for most accurate & speedy design change over

|

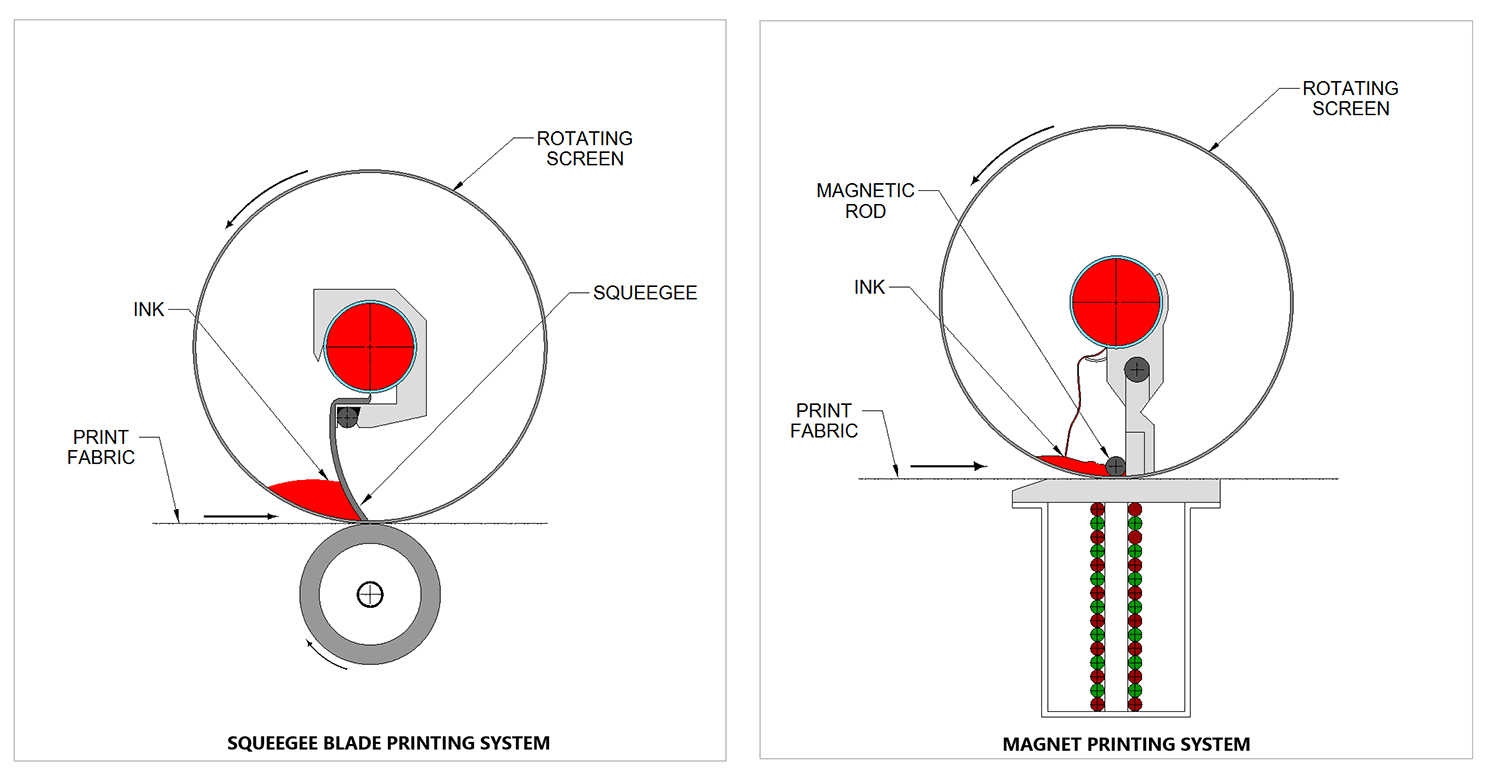

SQUEEGEE SYSTEM |

A squeegee is a tool with a blade that removes or controls colours across surfaces.

A tool possessing a wooden or metal handle to which is attached a thin, flexible rubber or plastic blade. A squeegee is used in screen printing to force ink through the printing screen and onto the substrate |

|

Stainless steel body diaphragm pump for colour feeding system. |

Blanket washing unit

Sponge type blanket washing unit with spray pipe and recirculation system to reduce water consumption.

|

|

| |

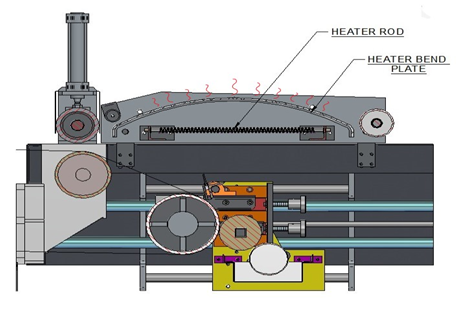

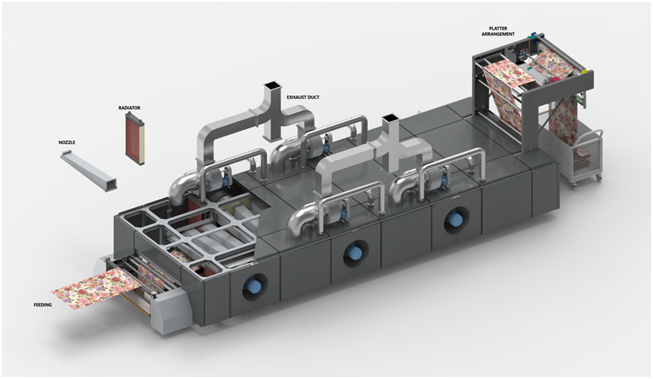

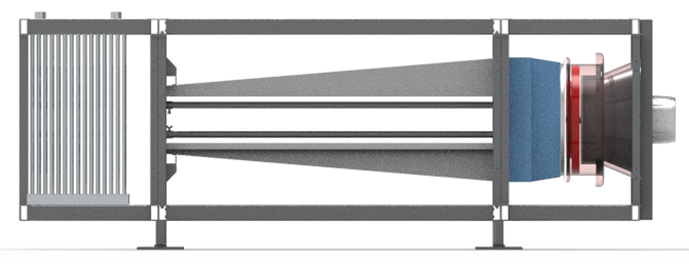

| HIGH EFFICIENCY DRYER |

| A dryer through which the printed cloth passes. A dryer is needed when printing with heat set inks which dry and set only with the application of heat |

|

|

|

| |

| OIL / STEAM HEATED DRYER |

WITH HIGH EFFICIENCY DOUBLE RADIATORS FOR EACH SECTION OF DRYER

- 4 RADIATORS PER CHAMBER EANABLES VERY HIGH DRYING CAPACITY & FASTER PRODUCTION.

|

|

|

| |

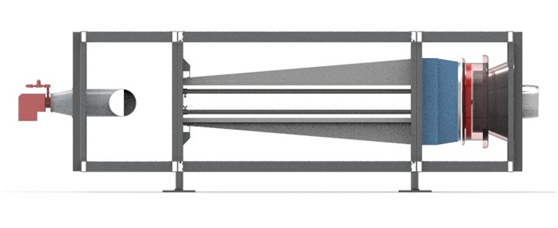

| GAS HEATING |

WITH CLOSE CIRCUIT DESIGN OF DRYER TO ENABLE VERY FAST GAIN OF DRYING TEMPERATURE WHICH ENSURE HIGH EFFICIENCY.

- UNIQUE FEATURES

- HIGH EFFICIENCY DRYER

- THE INGENIOUS NOZZLE SYSTEM

- ADJUSTABLE INVERTER-CONTROLLED AIR FLOW ENSURE UNIFORM TEMPERATURE DISTRIBUTION

- EASILY REMOVABLE LINT FILTERS AND NOZZLE FOR CLEANING

- SUPERIOR INSULATION PANELS FOR ENERGY SAVING

- MODULAR DESIGN OF CHAMBER

|

|

|

| |

| TYPICAL SCHEMATIC DIAGRAM FOR SCREENOTEX ENGINEERS RSPM |

|

|

|

|

|